Contact us

Mr. Altmann (CZ)

- contact_phone +420 379 738 778

- contact_phone +420 379 738 775

- contact_mail altmann@iol.cz

Mr. Henghuber (DE)

- contact_phone +49 171 547 5391

- contact_phone +49 872 796 9827

- contact_mail AHenghuber@aol.com

Product range

ADT On-line dehydrator

On-line dehydration and filtration of power transformers

- mobile unit, no disconnection of the transformer under treatment,

- installation and service with minimum manpower and energy

- quick restoration of dielectric strength of the oil

- no impact on the insulating oil properties

- no impact on DGA

- direct check of the dehydration efficiency by input/output reading of water content in oil and volumetric reading of oil throughflow

- easy replacement of adsorption columns

- SCADA features: remote monitoring & control of the drying process,on-line BDV check, internet, SMS connection

ADT Mini On-line dehydrator

On-line dehydration and filtration of power transformers

- mobile unit, no disconnection of the transformer under treatment, normally not

- installation and service with minimum manpower and energy

- quick restoration of dielectric strength of the oil

- no impact on the insulating oil properties

- no impact on DGA

- direct check of the dehydration efficiency by input/output reading of water content in oil and volumetric reading of oil throughflow

- easy replacement of adsorption columns

- SCADA features: remote monitoring & control of the drying process, on-line BDV check, internet, SMS connection

S-03

On-line dehydration and filtration of tap-changers

- primary aim of the S-03 is to maintain the required BDV level of insulation oil as

- a further advantage is the reduction of the frequency of otherwise unavoidable oil changes in the equipment.

- substantial reduction of the operating and maintenance costs.

SIMMS 2.2

In situ diagnostics of transformer

- easy and quick connection to the oil sampling points of a transformer

- automatic tracking of Tx temperatures and water content in the oil

- check of the temperature and water content equlibrium

- first data snapshot about a moistureand gas problem of a transformer already within 30 - 40 minutes

- evaluation of water content in hard insulants

- prediction of Tx-dielectric behaviour for whole temperature range

- verification BDV-prediction by lab results

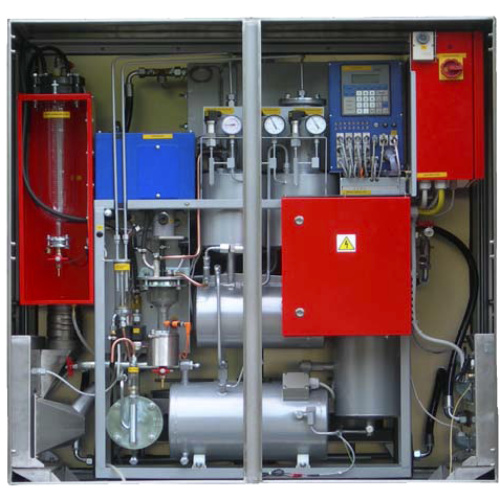

Vacuum separator VS-06

On-line dehydration, degassing and filtration of power transformers, controlled removal of fault gases

- mobile unit, no disconnection of the transformer under treatment, normally not even during the installation of a separator

- installation and service with minimum manpower and energy

- quick restoration of dielectric strength of the oil

- no impact on the insulating oil properties

- no over-drying of the transformer

- direct check of the dehydration efficiency by volumetric measurement of the separated water

- stripping - effective removal of fault gases

- direct check of the degassing efficiency

- remote monitoring & control of the drying and degassing process, on-line BDV check, SMS connection

- application of advanced and patented technologies like “hydraulic piston” for vacuum building and “bubble bed” for moisture separation

Vacuum separator VS-07

On-line degassing and filtration of power transformers

- mobile or unit, no disconnection of the transformer under treatment, normally not even during the installation

- installation and service with minimum manpower and energy

- Gas contents and particles content can be reduced to the level of a new transformer

- stripping - effective removal of fault gases

- Quick restoration of safe operation conditions

- Minimum moving parts, the gear pump works like an oil pump or a vacuum pump

- no impact on the insulating oil properties

- direct check of the degassing efficiency via volumetric reading of removed gases

- SCADA features: remote monitoring & control of the degassing process, internet, SMS connection